Introduction

NFES-100 is a bench-top electrospinning system for producing fibers with diameters from 20-1000 nm. The ultrafine fibers are produced from one or multi polymer solutions. In the Electrospinning process, electric-field-induced jets are used to draw nanofiber from viscous polymer solution bath, which are collected on metal collectors. A few hundred kinds of polymer available on the market for Electrospinning. The Electrospinning system has been widely used in the fields of material development, biomedical, photonics, and other fields requiring outstanding material properties.

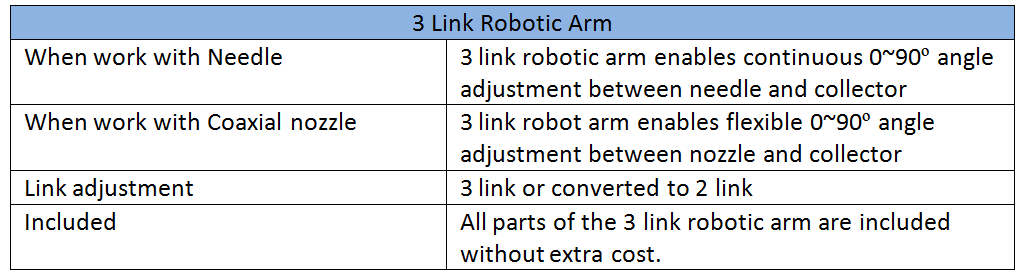

New features include a 3 link robotic arm enables continuous 0~90º angle adjustment between needle and collector. Each syringe pump carries two syringes, four syringes can be mounted in total.

Features

- Compact and high precision machine for producing fibers in nano scale;

- 3 link robotic arm enables continuous 0~90º angle adjustment between needle and collector

- PLC control for automatic mode, manual mode, and positioning mode, easy to operate and precise control

- Specially designed syringe pump supplying solutions continuously with adjustable flow rate, suitable for use with different types of solutions;

- Each syringe pump carries two syringe, four syringes can be mounted;

- High positive voltage power supply for long time operation, electric field continuously adjustable between 0 and 40kV;

- High negative voltage power supply for long time operation, electric field continuously adjustable between 0 and -10kV;

- Various collectors, mandrel, metal plate, Squirrel-cage, ultra-fine tube, round disc, high speed rotation orientation, negative pressure orientation, and double motor drive; customizable

- Modulated design, suitable for be customized for various applications.

- The Cabinet is equipped with a temperature control unit, a humidity control unit, and an exhaust duct, customizable to clients’ needs

- All devices and components are arc proof

- Most electrical components carry UL/CSA certificates

Technical Specifications

Recent Clients

National Academies of Sciences, Engineering, and Medicine, National Laboratories of USA, and University of Munich

Additional Notes

1. Lead time: 8 weeks

2. Assembled Canada, onsite services available

3. Free shipping for US and Canada

4. Accept custom OEM if there are any special requirements for your application

5. All university and institution clients from US and Canada are entitled to payment term of net 30 days automatically. No worry, No stress, No Risk.

6. All units of the system are customizable and can be purchased separately.

7. The machine is built to be safe and reliable. It is not CSA/UL certified.