Introduction

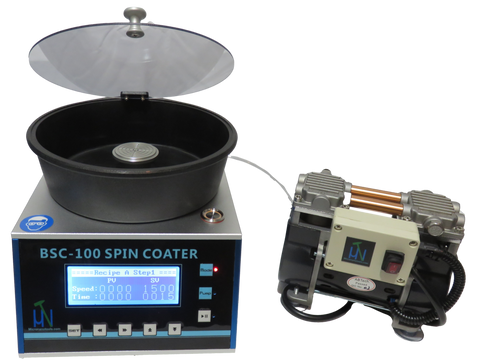

BSC-150, equipped with a microcontroller, is a high performance spin coater for precise and high uniform deposition of thin films and coatings on wafers up to 150mm or 6 inch. With its compact design, the BSC-150 can be installed in a glovebox or in a fume hood easily. An industrial grade DC motor enables the spin coater to reach maximum rotation speed of 12,000 RPM in a few seconds. In each spinning process, spin speed and spin time can be set up to five steps. Totally five processes/recipe can be stored in the system for easy access. Its rugged, vibration-free and portable design makes it a versatile tool for your research facility. The spin coater can be used to deposit metal oxide thin films, polymer coatings and metal organic thin films.

For customization of the main unit and vacuum chucks for your applications, please contact us.

If you find a lower price from an online retailer on an identical and in-stock product, please let us know and we'll match it.

Please contact us at 1-888-229-1281 or email info@micronanotools.com for more details.

Features

- 200mm internal chamber, designed for wafers from lateral dimension of 10mm up to 150mm in diameter

- Powerful industrial grade 100W DC brushless motor, adjustable between 100 and 12,000 RPM with controlled acceleration between 100 and 3000rpm/s

- Safety interlock realized by lid sensor and vacuum sensor.

- Robust design: Vibration free, stable spinning, low noise level

- Stainless steel body with chemical resistant transparent PC lid, built to last

- Compact design, easy to pass antechamber of glovebox

- Microcontroller with 4.3 inch touch screen enables precise and automatic operation of the system

- Programmable 10 steps process for each recipe and 10 recipe can be stored in microcontroller

- Fully customizable vacuum chucks according to size and geometry of substrates, and coating material

- Oil-less vacuum pump included, with stand alone control and anti-slip base

- The bowl of the spin coater is removable and can be cleaned easily

- Designed to prevent photoresist blocking

- Lid sensor ensuring the spin bowl lid is closed during the spin process

- Vacuum sensor monitoring the vacuum status ensuring the substrates are firmly held to the spin chuck during high speed spin process

Specifications

Optional Accessories

Warranty

- Two years standard warranty for both parts and services with life-time support

- Damage due to improper operation or maintenance is not covered by warranty

Partial List of Recent Clients for Spin Coater

Brookhaven National Laboratory, Duke University, Sandia Nation Laboratory, University of Waterloo, University at Buffalo, Purdue University, Fresh Air Sensor, Texas A&M University, University of Maryland at Baltimore, University of Akron, University of Toronto, Middle Western University, Northeastern University, University of Louisiana, Carnegie Mellon University, University of Washington, Lehigh University, and Georgia State University, Technical University of Denmark, Waves Audio Ltd, Indiana University, VISITECH in Norway, Northwestern University, EMPA in Switzerland, Midlands Technical College, Allergy Amulet, Kent State University, Carnegie Mellon University, MRIGlobal, Laserinstitut Hochschule Mittweida in Germany, Iowa State University, Terabase Inc. in Japan, Kansas State University, Leticia Canales, Northern Arizon University, Sensient Technology, Ubeam, University of California in San Diego, Univeristy of Notre Dame, University of Southern Mississippi, Washington State University, Furcifer Inc., Alberta University, Arizona State University, State University of New York at Buffalo, California Institute of Technology, Carbon3D, Clemson University, Louisiana State University, Midwestern University, National Institute of Standards and Technology, Princeton International School, San Jose State University, Sero Immuno Diagnostics, State University of New York, State University of Oregon, University of Akron, University of California, University of Oregon, University of Toronto, USARL, North Dakota State University, Technical University of Denmark, McGill University, Virginia Tech, University of Montana, Towson University, Norfolk State University, Forcyte Biotechnologies

Additional Notes

- The item will be shipped in three business days after the payment is cleared

- All university clients from US and Canada are entitled to payment term of net 30 days automatically. No worry, No stress, No Risk.

- Seller from Canada, on site local services available for heavy equipment upon request

- Free shipping for US and Canada, duty, and custom clearance all included in the price when applicable

- Accept custom OEM if there are any special requirements for your application